Our line of compact installation and valve material is submitted to thorough quality testing throughout the production and submitted to a leakage test before leaving the factory.

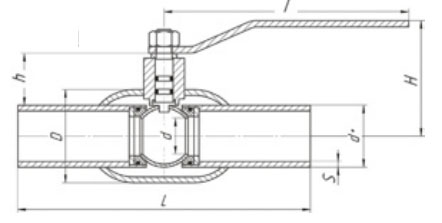

| DN | PN | d | d* | s | D | H | h | I | L | Bec,kr. | |

| 15 | 40 | DXQF50015000 | 10 | 21.3 | 2.8 | 38 | 72 | 23 | 170 | 200 | 0.8 |

| 20 | 40 | DXQF50020000 | 15 | 27 | 2.8 | 42 | 72 | 23 | 170 | 200 | 0.8 |

| 25 | 40 | DXQF50025000 | 18 | 32 | 3 | 48 | 75 | 21 | 170 | 230 | 1.1 |

| 32 | 40 | DXQF50032000 | 24 | 38 | 3.5 | 57 | 75 | 21 | 170 | 230 | 1.5 |

| 40 | 40 | DXQF50040000 | 30 | 48 | 3.5 | 60 | 92 | 44 | 235 | 250 | 2 |

| 50 | 40 | DXQF50050000 | 40 | 57 | 3.5 | 76 | 100 | 44 | 235 | 270 | 2.6 |

| 65 | 25 | DXQF50065000 | 49 | 76 | 4 | 89 | 110 | 44 | 235 | 280 | 3.4 |

| 80 | 25 | DXQF50080000 | 63 | 89 | 4 | 114 | 141 | 60 | 335 | 280 | 5.3 |

| 100 | 25 | DXQF50100000 | 75 | 108 | 5 | 133 | 150 | 60 | 335 | 300 | 6.7 |

| 125 | 25 | DXQF50125000 | 100 | 133 | 6 | 180 | 195 | 94 | 525 | 330 | 15.3 |

| 150 | 25 | DXQF50150000 | 125 | 159 | 6 | 219 | 210 | 98 | 525 | 360 | 20.6 |

| 200 | 25 | DXQF50200000 | 148 | 219 | 8 | 273 | 225 | 84 | 625 | 430 | 36 |

| 250 | 25 | DXQF50250000 | 200 | 273 | 8 | 351 | 270 | 100 | 625 | 510 | 54 |

| 300* | 16 | DXQF50300000 | 240 | 325 | 8 | 426 | 634 | 167 | - | 730 | 120 |

| 350* | 16 | DXQF50350000 | 300 | 377 | 10 | 530 | 690 | 196 | - | 730 | 230 |

| 400* | 16 | DXQF50400000 | 300 | 426 | 10 | 530 | 690 | 196 | - | 860 | 280 |

| 500* | 16 | DXQF50500000 | 390 | 530 | 10 | 630 | 870 | 170 | - | 970 | 450 |

Proven Product

Our line of compact installation and valve material is submitted to thorough quality testing throughout the production and submitted to a leakage test before leaving the factory.

Applications

Heating and Cooling Systems

Air, Water, Open and Closed Systems

Ethanol, Methanol, Glycol, Freezium, etc.

Available

In sizes from dn 10 to dn 500

With reduced bore

With weld connections according to en (din) standards

Also with flanged or threaded connections

With manual lever, manual gear, pneumatic, electric or hydraulic actuator

Fully welded construction

Light weight

Easy to insulate

Space saving design

Easy to install and use

Maintenance-free

Long service life

Total bi-directional tightness (en 12266-1, leakage rate a)

High kv value (minimum pressure loss, minimized pumping costs)

High-quality materials, suitable for many different applications

Spring loaded ptfe ball seals

Blow-out safe stem construction

Stem sealing with double o-rings