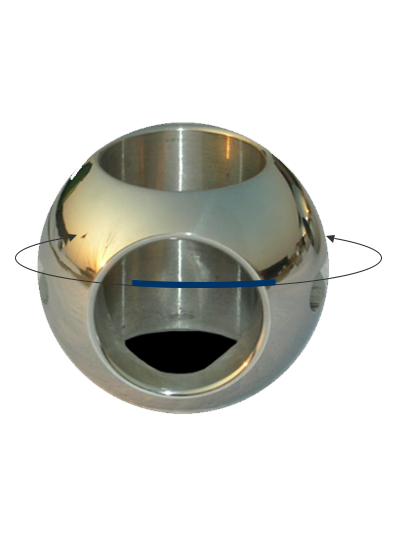

1. When decomposing and reassembling the ball valve which buy from Stainless Steel Hollow Ball Factory, care must be taken to prevent the sealing surface of the damaged part, especially for non-metallic parts. Special tools should be used when removing the O-ring.

2. After cleaning, it needs to be assembled after the wall cleaning agent is volatilized (can be wiped with silk cloth without dipping cleaning agent), but it should not be left for a long time, otherwise it will rust and be polluted by dust.

3 New parts should also be cleaned before assembly which from Carbon Steel Floating Ball Factory.

4. Lubricate with grease. Grease should be compatible with ball valve metal materials, rubber parts, plastic parts and working media. When the working medium is gas, for example, special 221 grease can be used. Apply a thin layer of grease to the surface of the seal mounting groove, apply a thin layer of grease to the rubber seal, and apply a thin layer of grease to the sealing surface and friction surface of the valve stem.

5. Metal debris, fibers, grease (except for the use) should not be allowed to be contaminated, adhered or stuck on the surface of the part or enter the inner cavity.

Previous: Use Of Ball Valves A