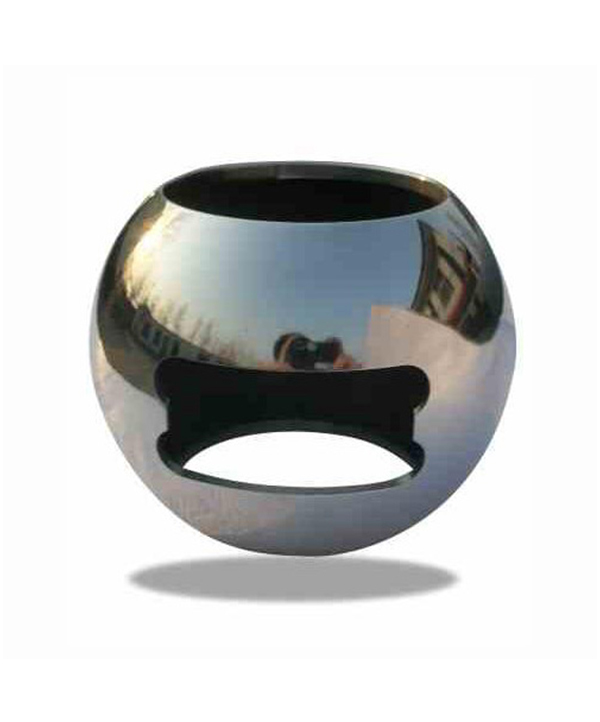

The Stainless Steel Hollow Ball works by rotating the ball to make the valve unblocked or occluded. The ball valve switch is light in weight, small in size, can be made into a large diameter, reliable in sealing, simple in structure, convenient in maintenance, and the sealing surface and the spherical surface are often closed, and is not easily eroded by the medium, and is widely used in various industries. Ball valves can be divided into 19 categories, including floating ball valves, fixed ball valves, metal hard seal ball valves, V-type ball valves, wafer ball valves, thermal ball valves, pipeline ball valves, track ball valves, top-loading ball valves, pigging valves, high-pressure forged ball valves, Three-way (four-way) ball valve, internal thread ball valve, integral ball valve, low temperature ball valve, bellows ball valve, eccentric hemisphere valve, all welded ball valve, special ball valve, etc. O-type ball valve from Stainless Steel Hollow Ball Manufacturer adopts floating structure, the core is precision casting, the surface is hard chrome-plated, the valve seat is made of metal or reinforced PTFE material, the flow port is the same as the pipe diameter, the circulation capacity is great, the flow resistance is very small, close No leakage, generally used as an on-off valve, especially suitable for high viscosity, fiber-containing, granular media. The V-type ball valve adopts a fixed structure, and a V-shaped slit is formed in the core to realize proportional adjustment, and the flow characteristics are approximately equal percentage.