Ball valves have many outstanding advantages over other valves. The main functions are as follows:

1. The ball valve has lower fluid resistance and has the lowest flow resistance (actually zero)

Ball valves typically have a reduced diameter and a path that is not reduced. Regardless of the structure, the flow resistance coefficient of the ball valve is relatively small. In particular, the so-called full-flow type, that is, the ball valve that does not reduce the diameter, because the passage diameter is equal to the inner diameter of the pipe, the length of the pipe is better in the rocket launch and its test system.

2. The ball valve opening and closing switch are quick and convenient.

3. The ball valve has good sealing performance.

Currently, valve seats for ball valves are typically made of an elastic material such as Teflon, and a sealed pair of metal and non-metallic materials is commonly referred to as a soft seal. In general, it is easy to ensure the sealing of the soft seal, and the processing precision and surface deposition requirements of the sealing surface are not high.

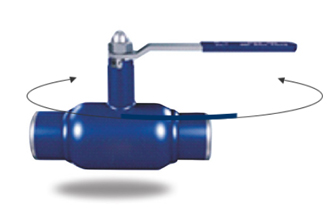

fully welded ball valve

4. The high reliability of the ball valve is mainly because:

A pair of seals of the ball and the valve seat will not be scratched, worn or otherwise broken, and will not get stuck during operation (without pressure), so it can be reliably applied using porous media and low boiling point liquids;

The built-in valve stem structure eliminates the hidden danger of the valve stem flying out due to the looseness of the packing gland under the action of fluid pressure;

Using anti-static refractory ball valve, suitable for conveying oil, natural gas and natural gas pipelines.

The valve body channel is flat, easy to transport the transport fluid. Slurry and solid particles.

5. Because it can not get stuck during work (no pressure), so it can be used reliably in worms and low boiling liquids.

6. The spherical closing member can be automatically positioned and can withstand the high-pressure difference at the time of closing.

7. In the axial pressure and temperature range, can achieve full-way two-way sealing.

8. When fully open and fully closed, the sealing surfaces of the ball and seat are isolated from the media, so that media passing through the valve at high speed does not cause corrosion of the sealing surface.

9. Compact, lightweight, can be considered the most reasonable valve structure for low-temperature media systems.

We can provide high quality fully welded ball valves, pls feel free to contact us.

Previous: None