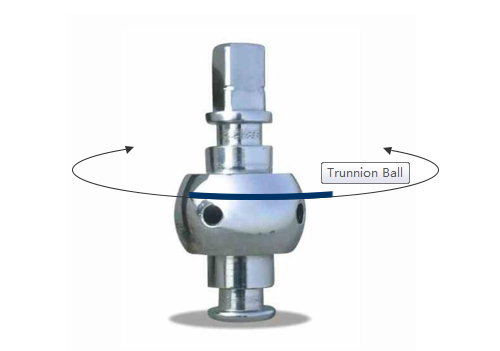

According to the force of the Trunnion Ball blank

(1) Hand forging processing: The forging of the blank is forged into a predetermined shape on the anvil by the force of the hand forging tool box.

(2) Machine forging: The forging is made into forgings on various forging equipment by means of a forging tool. Machine forging can be divided into four categories of OEM Stainless Steel Trunnion Ball: free forging, model forging, film forging and special forging, depending on the equipment and tools used.

1 Free forging: It is to forge a metal blank heated to a certain temperature between the upper and lower anvils of the free forging equipment, and the operator controls the deformation of the metal to obtain the forged piece of the desired shape.

2 model forging: referred to as die forging. It is a method for producing a forging that conforms to a mold cavity by placing a metal blank heated to a certain temperature into a mold cavity fixed to a die forging apparatus for forging and limiting deformation thereof.

3 film forging: referred to as fetal film forging. It is a deformation method between free forging and die forging. The metal blank heated to a certain temperature is freely forged by a film that is not fixed to the free forging device to obtain a formed forging.

4 Special forging: It is a forging process for forming metal blanks on special equipment or in special molds. Such as precision forging, roll forging, rolling, spiral rolling, transverse rolling, extrusion and so on.

Previous: Use Of Ball Valves B